|

30kWOTEC

OTEC and Desalination Room

|

|

Experimental and corroborative works of OTEC technology with the Uehara Cycle, which is our own invention at this IOES, are being carried out in this room. Also a hybrid type OTEC technology combined with desalination system is another objective here. The output capacity of the pilot OTEC plant is 30kW, while the desalination test plant has a production capacity of 10 tons per day.

|

| Heat Exchanger Room |

|

Successful utilization of the ocean energy depends on how effectively we can handle small differential temperature between warm and cold water. Hence, efficiency of heat exchanger is one vital element for the success. We are conducting research on basics and application advantges of various types of heat exchangers. Plate type heat exchanger sits in the center of our evaluation studies.

|

| Hydrogen Experimental Room |

|

Production, storage and utilization study of hydrogen, a substance being evaluated highly as the indispensable energy of next generation, is going on in this room. You will find in this room various apparatus including fuel cells. It is to be of particular interest to know that hydrogen is obtainable through electrolytic process utilizing both pure water and electricity produced by our hybrid type OTEC system.

Production capacity of hydrogen: 1 Nm3/h, purity - more than 99.9999%.

Storage capacity of hydrogen by two tanks made of Metal Hydride: The larger one is 10 Nm3, while the smaller one is 1 Nm3.

Fuel cell: Polymer Electrolyte Fuel Cell (PEFC) type with output capacity 900W

|

Deep Seawater Simulation Room

|

|

This equipment simulates various conditions in deep sea. Particularly, observation of flow of seawater, distribution of temperature and salt density, wave and wind are the objectives by this facility. The water tank provided in this equipment is 10m (l) x 1m (w) x 1.6m (d), while actual depth we can go is 1.2m. Water temperature and flow rate of water are adjustable within 5~35℃ and within 0.8~5.5 cm/s respectively.

Our current theme to work with this equipment are, among others, enrichment of fishing ground, intake and discharge system of seawater for OTEC operation, utilization of wave energy, interrelated effect between seawater and environment.

|

| Wave Tank |

|

The wave tank, which can generate regular and irregular waves corresponding to ocean waves, was installed in order to develop the wave energy converter. It has an absorbing wave generator at both ends of the tank.

|

| Circulating Water Channel |

|

The circulating water channel is provided for the tidal power generating tests. This device has 9.0m long, 1.0m width and 4.0m height. The dimension of the measuring section is 2.5m long, 1.0m width and 0.9m depth (0.7m water depth). We can change the current velocity within a range from 0.0m/s to 1.5m/s by the control panel. |

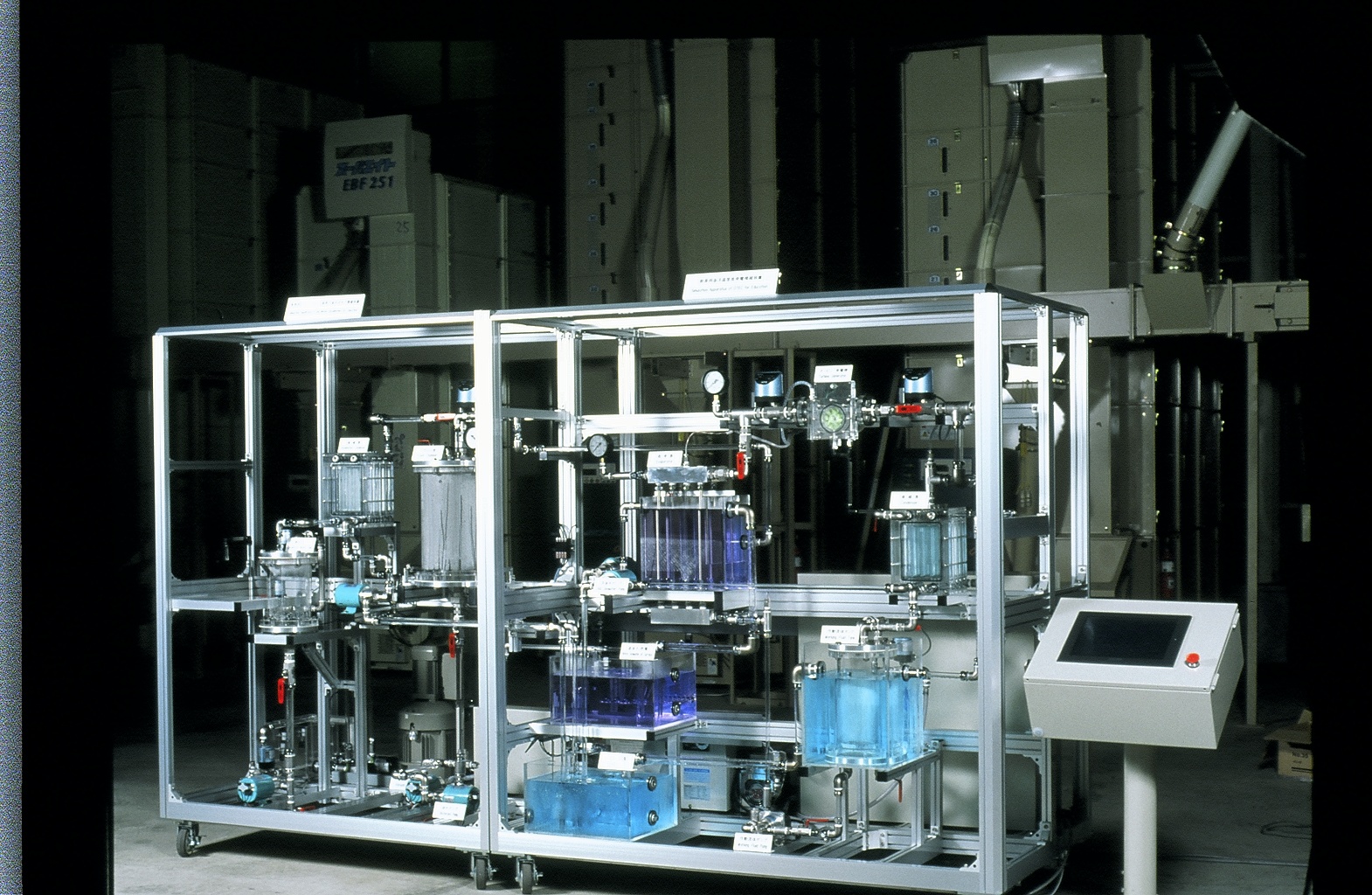

| Lithium Recovery Room |

|

The selective recovery technology for lithium from seawater is one of the most promising solutions to our energy issues. Although the concentration of lithium in the ocean is very low at 0.1-0.2 ppm on average, a novel technology that selectively recovers only lithium from amonga all other coexisting ions (e,g, sodium over 10,000 ppm) is necessary. Our lithium recovery system, with a fully automated operating system, consists of a separation column packed with an original lithium adsorbent, an intake unit for seawater, and concentration apparatus for lithium crystallization.

|

| Central Monitoring Room |

|

From the central monitoring room we monitor and control all sections of the entire facility at IOES. We are currently developing a new and advanced system to utilize the Internet to allow us to monitor and control all systems remotely from outside the facility.

|

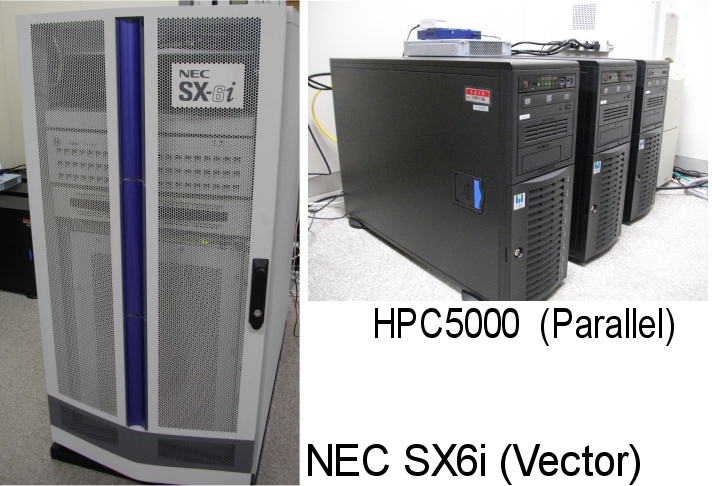

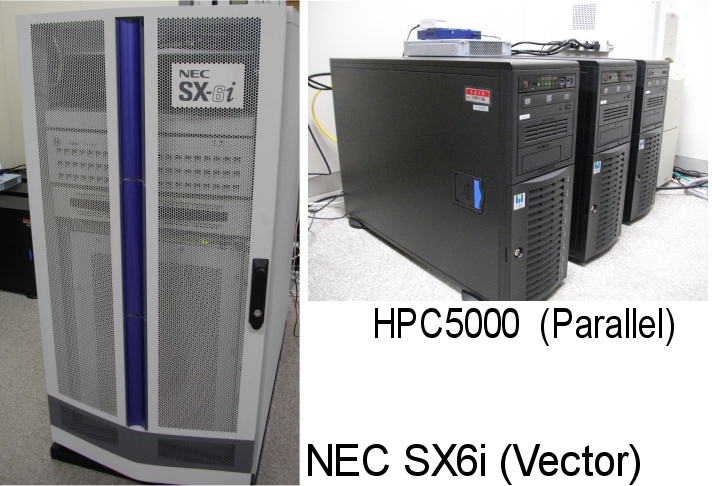

| Super Computer Room |

|

In this room you will find Vector computer model NEC SX6i and Parallel computers model Compaq Alpha Server ES45 and model Compaq Alpha Station DS25. The former performs high-speed calculation of simulated environmental conditions of fluids like those of deep seawater, while the latter two do simulation calculation very effectively by molecule dynamics used for evaluation of L i extraction experiments.

|

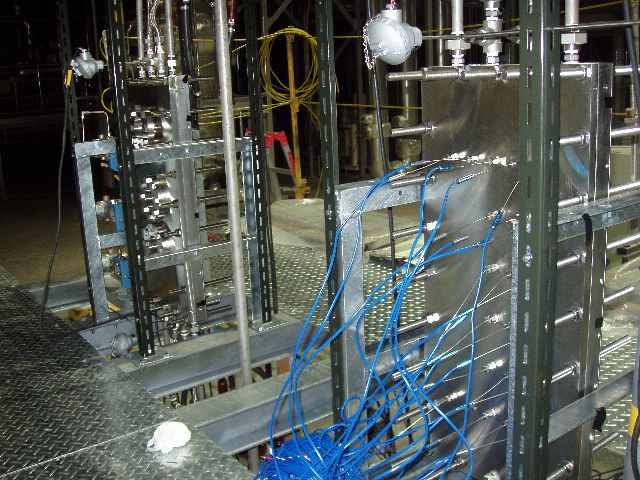

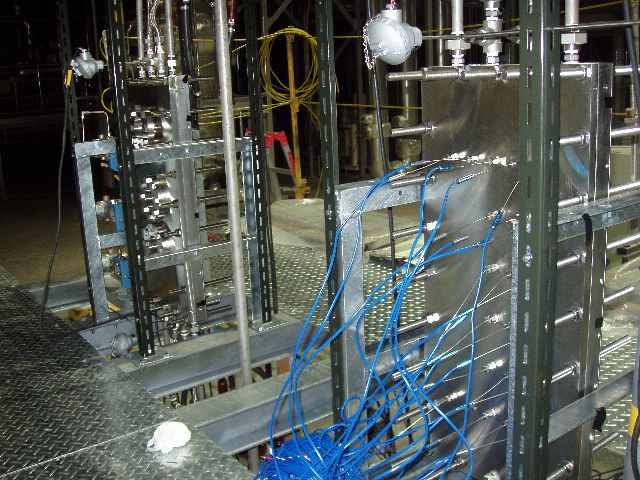

| Experimental Device for the Study of Antifouling |

|

As the OTEC power plant utilizes raw (untreated) seawater, the efficiency of heat exchangers can be reduced during OTEC operations due to the attachment of microbes found in seawater. IOES has been successfully experimenting with an ozonizing method, finding that a momentary injection of ozone into seawater achieves a good effect.

|

|

Seawater Upwelling Pipe

|

|

For research and development of utilization technology of the ocean energy it is of a particular importance that we actually deal with seawater. A case study of bio-fouling in the heat exchanger won’t be possible if we don’t apply actual seawater. Also, seawater enables us study different operational conditions caused by its varying temperature. Needless to say, for desalination tests and for extraction experiment of lithium we do have to have seawater. Our pipe can handle maximum 1,000 ton per day.

|

|

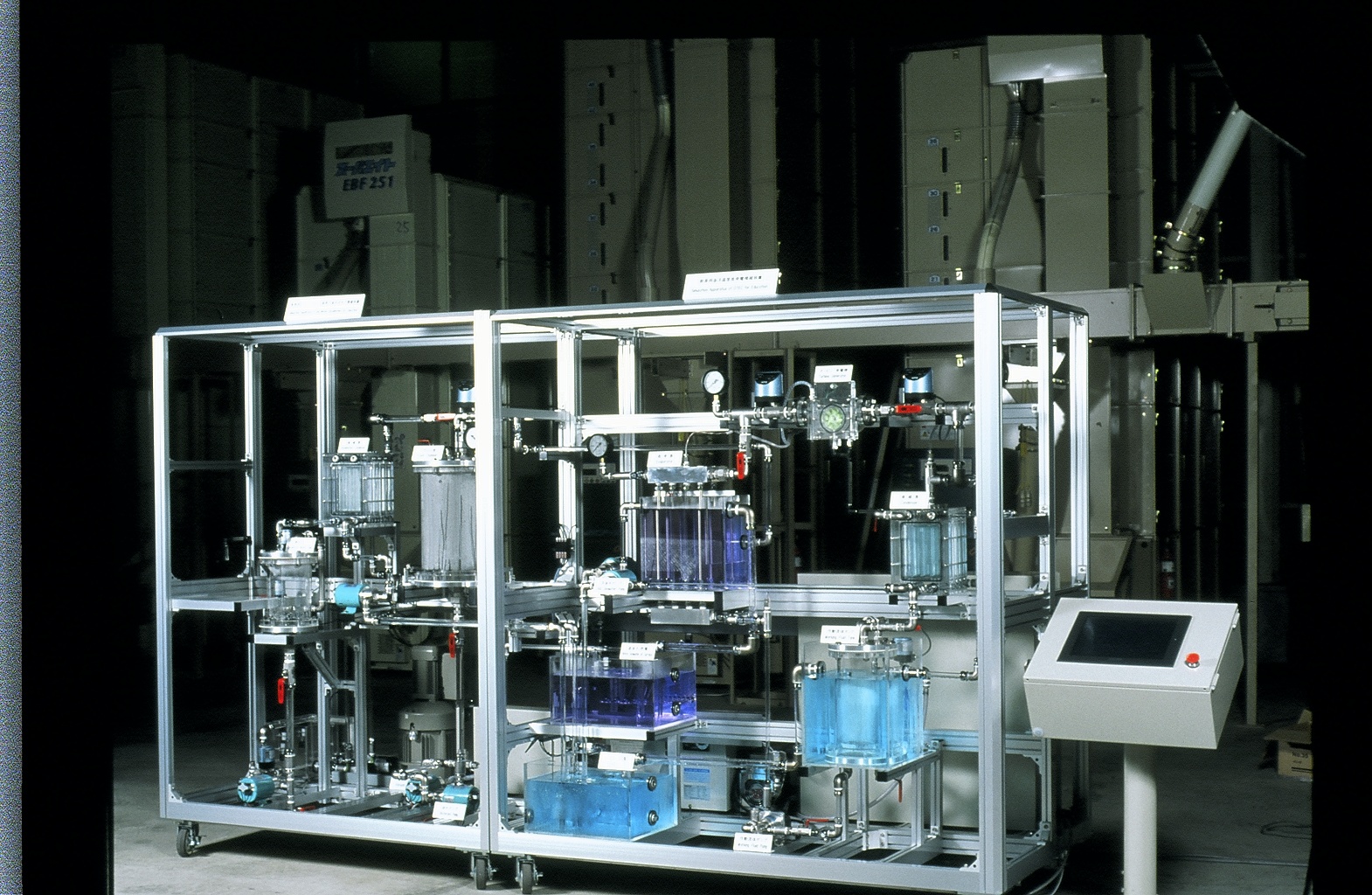

Mini Model of OTEC Process for Education

|

|

It is impossible to take a look of the inside conditions of component parts during operation of the pilot OTEC plant. This mini-model is built for educational purposes and serves to offer visual understanding of the simulated OTEC technology and desalination system respectively.

|

| Earth Observation Satellite Data Acquisition and Processing System |

|

The earth observation satellite data acquisition and processing system allows us to acquire useful data of oceanic energy-related information from space. This system uses many satellites that observe the earth during more than 10 orbits per day. The system also allows the database server function to be accessed by qualified users through a network as well as by physical media.

|